TPA-10A Kit per punzonatura idraulica con fori a colpo, set per fori su tubazioni elettriche da 1/2 a 2 pollici, attrezzo per punzonare lamiere metalliche

|

Uscita : |

8T |

|

corsa: |

22mm |

|

Numero di Modello: |

TPA-10A |

|

intervallo di punzonatura della piastra di ferro: |

3mm |

|

Quantità Minima di Ordine: |

1 Set |

|

Prezzo: |

US$ 85.00 |

|

Dettagli Imballo: |

Scatola di plastica |

|

Tempo di Consegna: |

≥3 giorni |

|

Condizioni di pagamento: |

c utilizzabile |

|

Capacità di fornitura: |

Disponibile |

- Panoramica

- Descrizione

- Prodotti consigliati

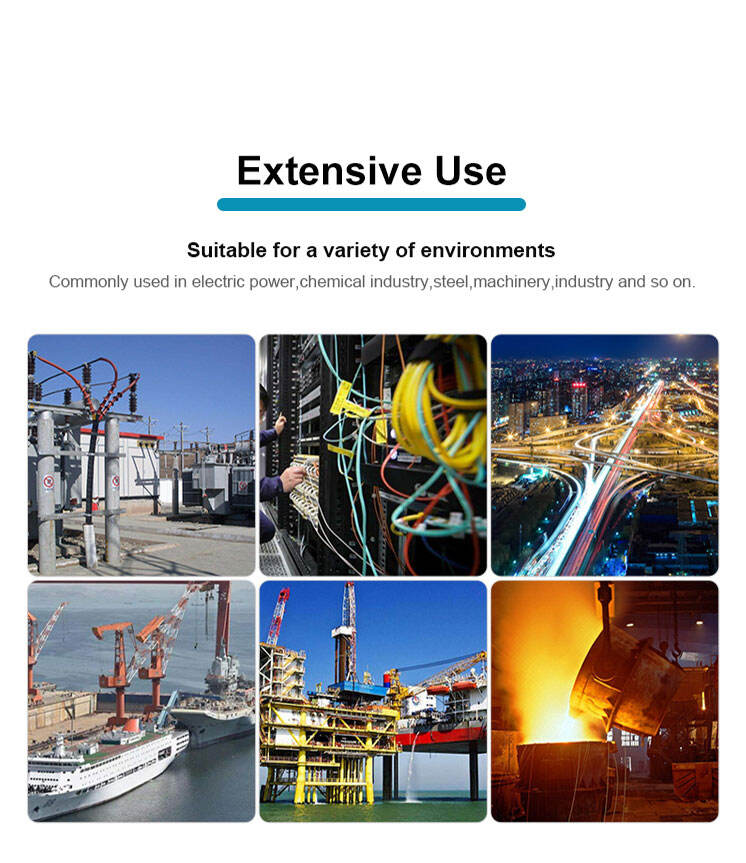

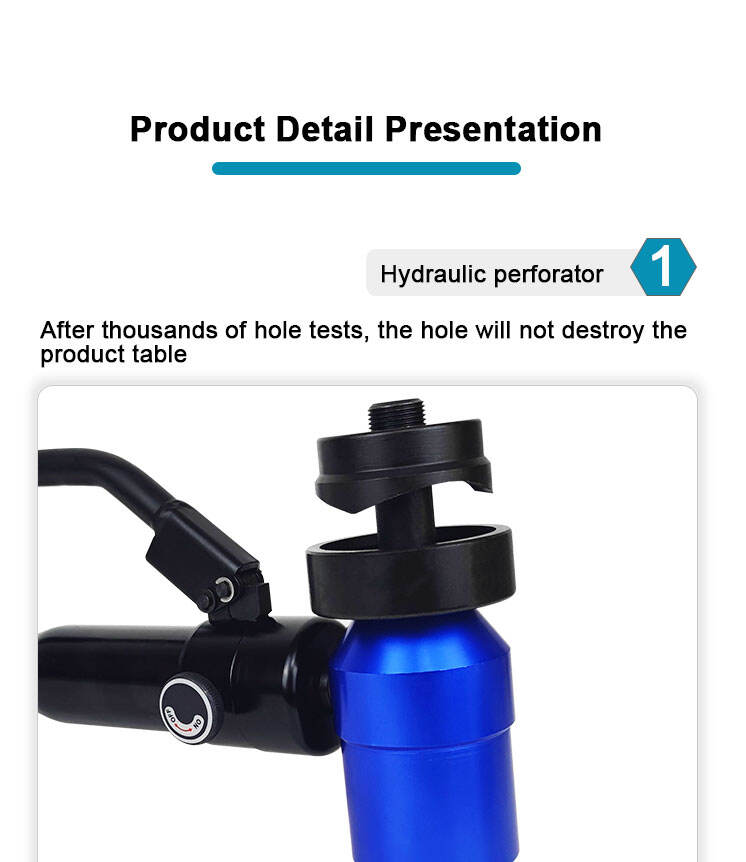

- Punzonatrice idraulica: dopo migliaia di test di foratura, il prodotto non subisce danni alla superficie

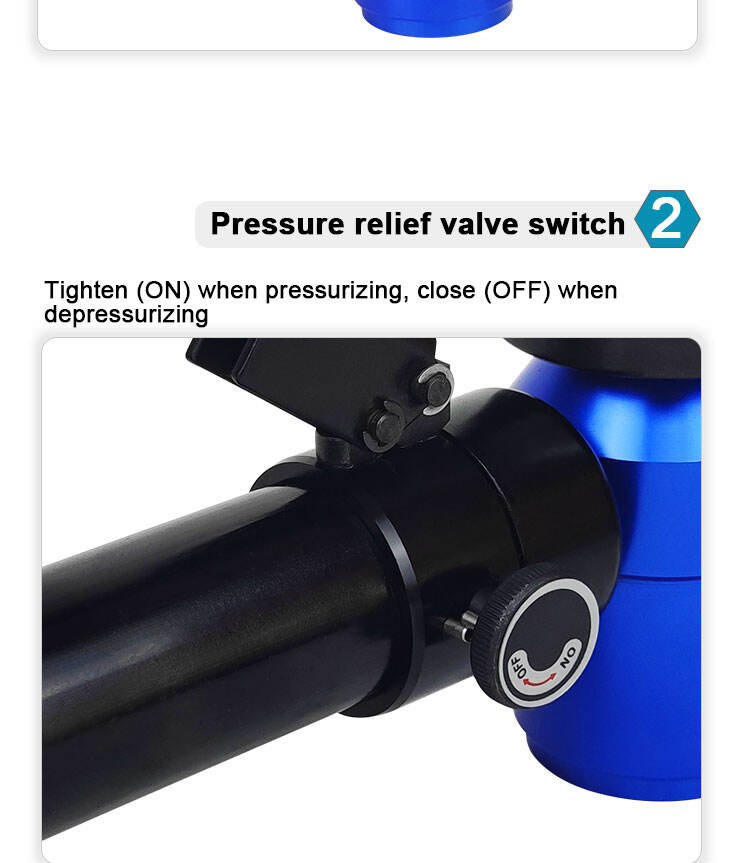

- Valvola di sicurezza: stringere (ON) durante la pressurizzazione, chiudere (OFF) durante la depressurizzazione

- Manico ergonomico in gomma, aumenta l'attrito manuale, più comodo da utilizzare

- Imballaggio in scatola di plastica, facile da trasportare e da portare