Understanding how single acting hydraulic cylinders work can allow you to make troubleshooting checks when these key hydraulic components refuse to function. Single acting hydraulic cylinders are common in factories and other places because they are both efficient and simple. These cylinders are strong, metal muscles that enable machines to lift and move heavy things easily.

Why single acting hydraulic cylinder As soon as we have a chance, for various purposes, to use at the factory, we entered the shadows instead of all kinds of vehicles and for single acting hydraulic cylinders? They are tough and can carry heavy loads. They move well and are user-friendly and easy to maintain, making them favorites among workers.

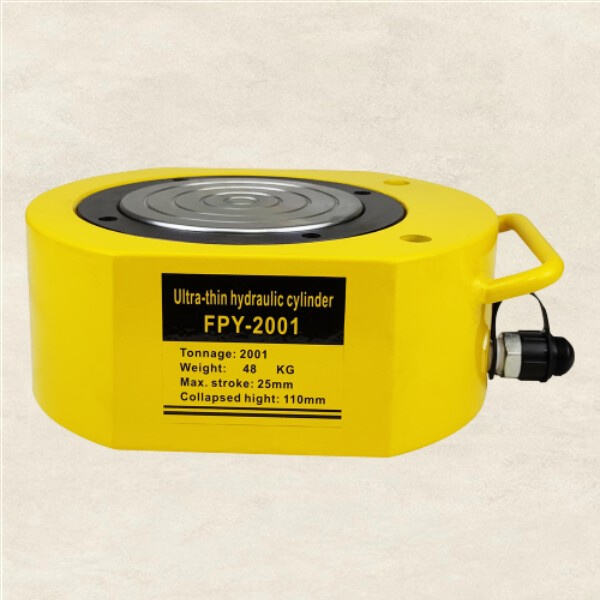

How Single Acting Hydraulic Cylinders Work: What Do They Need? These cylinders have a piston that moves in and out of a tube. This force and motion is generated by the movement of hydraulic fluid. Single Acting Hydraulic Cylinder Parts A single acting hydraulic cylinder has only four parts which are the cylinder, hydraulic fluid, piston and the seal to keep the water moving.

Looking at single acting cylinders vs double acting cylinders might help you decide whether to use one or the other on a project. Single acting cylinders rely on hydraulic pressure to push the piston out; other forces are required to return it to its original place, such as gravity or springs.Double acting cylinders rely on hydraulic pressure to push and pull the piston, and are therefore suited for many types of work.

In order for single acting hydraulic cylinders to work smoothly, they must be well maintained. Keeping an eye out for leaks and replacing worn seals can prevent problems down the road. If you’re having problems, such as sluggish movement or unequally lifting, troubleshooting can help identify and resolve issues easily.

Our extensive portfolio includes hydraulic crimping, cutting, bending, and pressing tools, all certified with CE and ISO 9001, ensuring safety, quality, and compliance for use across global industries such as power, shipbuilding, and construction.

Backed by a skilled R&D team of industry experts and senior engineers, we consistently develop and upgrade products, maintaining technological leadership and offering custom solutions tailored to evolving market needs.

We uphold a customer-first approach, providing end‑to‑end support from pre‑sales consultation to after‑sales service, building lasting trust through professional communication, competitive pricing, and reliable product performance.

Equipped with advanced production facilities and efficient inventory management, we support large‑scale orders with fast lead times and dependable delivery, serving markets across Europe, South America, Southeast Asia, and the Middle East.

Copyright © Yuhuan Changyou Hydraulic Tools Co., Ltd. All Rights Reserved - Privacy Policy - Blog